FMTech Insights: Asset Management - A Live View of the Equipment Fleet

FMTech Insights is a series where subject matter experts and thought leaders in FMTech share their knowledge and opinions on the topic of their expertise; helping the industry learn, innovate and grow. The series will cover every sector in FM – from workplace management, operations and maintenance, energy management, waste management and everything in between.

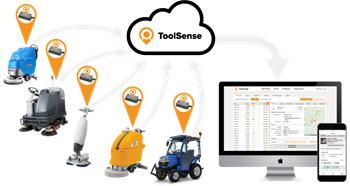

Alexander Manafi is the CEO & Co-founder at ToolSense which allows you to digitize your machine and service management, keeping track of mobile machines (those big machines used in cleaning, for example). It does this through a simple scan of a QR code in the machine which digitizes issue reporting and machine ticketing. ToolSense IOT hardware installed in the machines is a "Plug & Play" IoT hardware that allows you to easily and cheaply network machines from any manufacturer .

FMTech Insights: Asset Management - A Live View of the Equipment Fleet

Currently, there is an increasing awareness in the industry that neglecting asset management entails high hidden costs or has a direct impact on work processes and communication channels in many places.

The topic ‘asset management’ has been so far neglected in the cleaning industry. There is still a lot of potential for increasing efficiency. With new technologies — such as the Internet of Things (IoT) — this potential can be tapped.

The average direct costs for equipment and resources are only five to seven percent of the total annual costs. For a long time, they were understandably regarded as a side issue. Currently, there is an awareness in the industry that neglecting asset management entails high hidden costs or has a direct impact on work processes and communication channels in many places.

In this context, the unloved topic of inventory comes to mind. There is often a great deal of uncertainty in companies about the total stock of equipment and resources, which value often exceeds millions of pounds. Or the all too often inadequate or even completely forgotten inspections of, for example, electrical assets (PAT-Testing) and ladders due to incorrect implementation, planning, and documentation.

In an industry like cleaning, where every cent is turned over three times, there is still a lot of potential for increasing efficiency. Cleaning companies usually have mixed fleets or work with machines and assets from different manufacturers. The goal must be to standardize these operating resources.

The Status Quo

Currently, asset management in most companies is lived in two realities: On the one hand, there is a theoretical reality in the form of the ERP system and accounting in the back office. On the other hand, there is the practical reality in the field and with the site managers, which is reflected in numerous Excel lists that are updated once a year with great difficulty. Both realities often have little in common.

As a result, this leads to numerous expensive problems:

Problem 1: Testing of assets and equipment is typically planned manually by the site manager, carried out by the service partner in paper form and in some cases documented very heterogeneously. This means that there is little comparison or traceability. In addition, the inspections entail high costs of between 15 and 30 pounds per asset. The site managers could do this actually on their own with suitable digital tools.

Problem 2: Purchase decisions are still very subjective today. The reason for this is that there is a lack of data to make fact-based decisions. Equipment is purchased that is a few pounds cheaper, but then causes several thousand pounds in maintenance costs during operation and causes additional process costs.

Problem 3: Often, big equipment is not necessary at all, as it is ultimately purchased. As a result, this equipment is not used frequently and ties up valuable capital. Or the other way around: Perhaps you would need actually one bigger machine and could save many cleaning hours.

Problem 4: Up to now, service processes have mainly been carried out manually, which costs the site managers a lot of time. In addition, service processes are regularly triggered because of trivialities, which in turn can cause high costs.

Problem 5: Due to manual inventory in the ERP-system or based on Excel, most companies do not have an overview of the actual asset inventory. This sometimes causes additional costs between 10 and 20 percent of the annual machine costs.

With all the difficulties faced in asset management, new technologies such as the Internet of Things (IoT) can provide valuable services.

But here, cleaning companies face two main challenges:

Manufacturer silos versus mixed fleets: Typically, cleaning companies have mixed fleets, i.e., assets from several manufacturers. Currently, it can be observed that almost every manufacturer is trying to launch their own proprietary silo solution for the management of their equipment. However, the cleaning company usually has a limited interest in being so closely tied to a machine supplier, or would like to retain a certain degree of independence.

Running costs versus economic requirements: Today's digitization solutions from manufacturers sometimes cost between 10 and 30 pounds per asset and month. This is too expensive for most cleaning companies and does an economically viable business case very difficult. The reason for these high costs is that the majority of machine builders follow the traditional approach of data streaming.

The technical implementation

In order to enable a comprehensive and at the same time efficient digitalization of asset and resource management, it is first necessary to consider the different areas of application and functionalities of the resources.

The goal should not be to create a "chicken-and-egg" solution that can cover everything, but rather to put together an intelligent symphony of different connectivity options: from wireless IoT modules to Bluetooth tags or NFC transponders to QR codes.

All these technologies can also be linked together: for example, the Bluetooth tag on the hoover can communicate with the IoT module in the automatic scrubber-dryer. This is a small intelligent box that is connected to the machine and then acts as a gateway to collect the fleet's data, process it and send it to the cloud in a DSGVO-compliant manner using a SIM card. This saves costs and creates wide-ranging coverage.

It is also important to think carefully about what data is needed to optimize economic decision-making and operational processes. Think, for example, of automatic messages when the machine leaves its assigned location or is moved outside core hours. A technology that has proven itself in this regard is so-called edge computing. Here, the data is continuously analyzed on the IoT module directly attached to the machine and only the findings relevant for an evaluation are sent to the cloud.

It is also significant to choose a scalable IT infrastructure that can cope with high data volumes and workloads — such as Microsoft Azure or Amazon Web Services (AWS). In the past, many companies have relied on their own in-house servers and on-premise solutions.

Finally, it is important to ensure that the system is easy to use and also suitable for mobile use. Employees are usually under a lot of time pressure and must be able to find their way around quickly. If this is not sufficiently given, the employees may not use the systems and revert to the old familiar — for example, to Excel and paper.

Live in a few days

There are already systems on the market, such as ToolSense, that make it easier to get started with digital asset management, also the mentioned advantages of the IoT technologies can be used within a few days. Experience shows that a cleaning company with a turnover of around 30 million pounds can save between 10 and 20 percent of machine costs and reduce annual inspection costs by up to 70,000 pounds with a proper asset management system. And the site managers save up to 100 hours of working time per year.

In addition to service providers such as ISS or WISAG, suppliers such as Numatic, i-team, Cleanfix, Columbus, STIHL, and many others also use the ToolSense platform and IoT hardware.

Disclaimer: the opinion of the author does not necessarily reflect that of the Global Alliance of Facility Management Innovators.